spray foam insulation

Spray foam insulation is most commonly comprised of an open or closed-cell Polyurethane foam and is abbreviated SPF (spray-polyurethane-foam). The advantages that spray foam insulation has over other tpyes of insulation (batt and rigid) are it’s molding characteristics and it’s air-sealing behaviour. It also resists thermal transfer very well and can last up to 30 years with proper installation. Spray foam insulation can become handy for tight, hard-to-reach areas for insulation and vapor retarding characteristics in the following areas: attic hatches, plumbing vents, recessed lights, duct raceways, windows, doors, rim joists, flues, soffits, wiring holes, etc. Spray foam is made by mixing components on the job site which almost instantly creates a chemical reaction which will later give way to an expanding sticky foam. SPF is typically installed via long hoses which pull the material from foam truck or trailer equipment. For the smaller projects, two-component tanks may be purchased in small tanks and installed by the advanced handyman of professional builder.

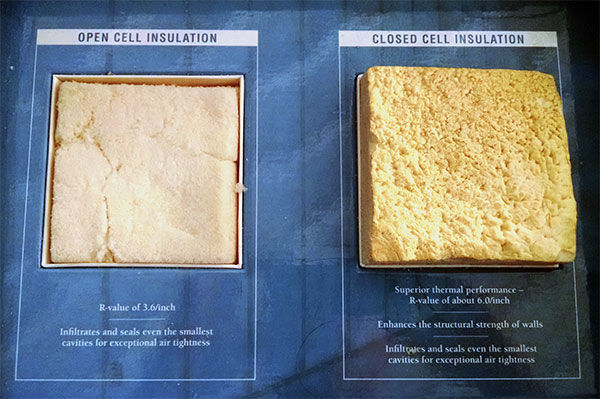

The options available are Open-Cell Foam and Closed Cell Foam. Open-Cell foam, often referred to as half-pound foam, is relatively vapor permeable, requires less material per volume, and will typically require use of a separate vapor barrier product.

CLosed-cell foam, often referred to as two-pound-foam, typically yields an R-Value of 6.5 per inch of material which is superior to most batt and rigid insulation types. Closed-cell foam is a vapor retarder, has low permeance (0.8 perms per 2.5″), and is typically more expensive than open-cell foam.

Open-cell foam typically utilizes carbon-dioxide or water as the blowing agent, while closed-cell foam is commonly blown in with hydrofluorocarbons (HFCs). HFCs however are becoming increasingly known as high-level ozone depletion byproducts so their use is becoming more limited with more builders and project owners.

There are 3 primary types of spray foam insulation for different applications:

Low Density

Very common for continuous insulation, filling cavities, and in attic without ventiliation. Some are made from raw bio-based materials which take the place of a portion of the petrochemicals.

Medium Density

Very similar uses as low-density only not often used as continuous insulation

High Density

Very common for roofing and exterior type applications

Some common things to avoid when installing Polyurethane Spray Foam is spraying the product too soon before the mixture components have gotten up to temperature for proper chemical reactions. Poorly mixed components, incorrect ratio, or incorrect temperatures can lead to a faulty product performance, particularly shrinkage and dislodging from the subtrate. Also rushed installation can lead to voids, cracks, and air spaces. Also SPF is very messy, so much so that prior prep work often requires taping and wrapping critical items in plastic is often a good idea