wood trusses

Wood Trusses are supporting structural elements which have a series of members acting in both tension and compression. They are utilized for roof or floor framing construction and are available in a variety of shapes and sizes. They are manufactured in controlled shops/plants and highly efficiently and most commonly with wood member sizes of 2×4 and/or 2×6. Trusses are fabricated by cutting to size and joining the members at toothed plate connections. The primary design factors that Architects will consider is the roof pitch, overall span, and overhang detail. It is commonly the truss manufacturers responsibility to utilize a known design to handle the live, dead, wind, and seismic loads or have an engineer custom design them. Shop drawings are commonly produced and submitted to the project architect/engineer for review. Pre-manufactured wood trusses will typically consume less wood than field framing and are assembled more efficiently in a plant environment often for lower workers wages than in the field. Trusses can be set with a crane relatively quickly in comparison to field labor from scratch, but some field installed blocking, joints, and assembly-joining carpentry will still commonly be required.

One downside of wood trusses is the significant amount of space they take up in an attic for other other rooms/storage or if a recess/opening is desired in the ceiling. However truss design and fabrication can overcome these types of restrictions if planned for ahead of time.

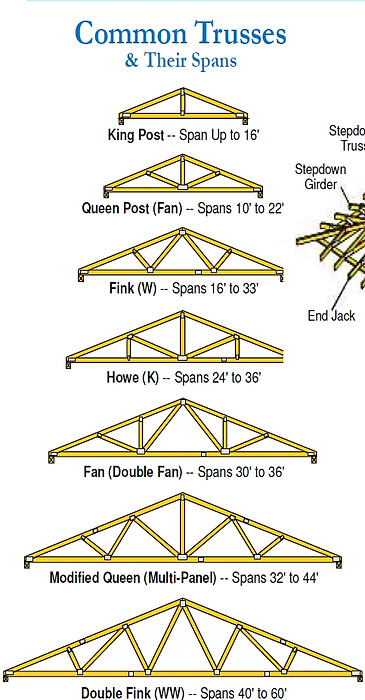

A truss is comprised of a bottom chord, top chords, and web members. Common truss types are the following:

Triangular – Coffer (Cove), Vault, Clearstory, cantilever, dual slope double-pitch, room-in-attic, gambrel.

Common – Fink (W), Howe (K) Fan, Modified Queen, Double Fink, Double Howe, Modified Fan, Triple Fink, Triple Howe, Three Piece Long Span, Three Piece Raised Center Bay

Triangular – Coffer (Cove), Vault, Clearstory, cantilever, dual slope double-pitch, room-in-attic, gambrel.

Continuous lateral braces or ‘Purlins’ are commonly installed directly above or below the top chord with 2×3, 2×4, or 2×6 blocking.

Depending on the span, the truss may be spliced (done at the plant) and most all truss member joints are attached with metal plates.

.jpg)

Typical truss On-Center spacing is between 2-4 Feet but wood trusses can be spaced up to 8′ centers depending on the spanning ability of the roof decking/sheathing. Overhang lengths are typically 2′ or less and fascia board will commonly be required along the ends of the truss (eave) with the soffit material being placed horizontally underneath the overhand.

The use of purlins allow wood trusses to be spaced even furher apart, sometimes as much as 20′ in extreme cases. Typical truss pitch ranges will fall between 2:12 and 8:12. Common truss depth ranges are between SPAN/10 and SPAN/20. The more common span range is 20-32′. For trusses spaced more than 2′, furring strips may be required to adequately support a ceiling installation with intended sheathed material.

Generally speaking, the following truss types can be spaced as outlined:

Shaped Trusses – 40-150′

Flat Trusses – 40-110′